-

Notifications

You must be signed in to change notification settings - Fork 171

Home

A cheap, snap-together, nearly screw-less 3D printer (reprap) design that minimizes use of non-printed parts. Current parts cost: $310! That's including the code of plastic used to print the parts!

| Link | Description |

|---|---|

| Make | If you need to make changes and regenerate the model files, here's how. |

| BOM | Bill of Materials. Those parts you need to print or obtain to make a Snappy. |

| Assembly | Instructions on how to assemble the Snappy 3d printer. |

It works! Undergoing progressive minor improvements.

2015-08-24

Currently undergoing tweaks to improve accuracy and print quality. Lots of iterative improvements.

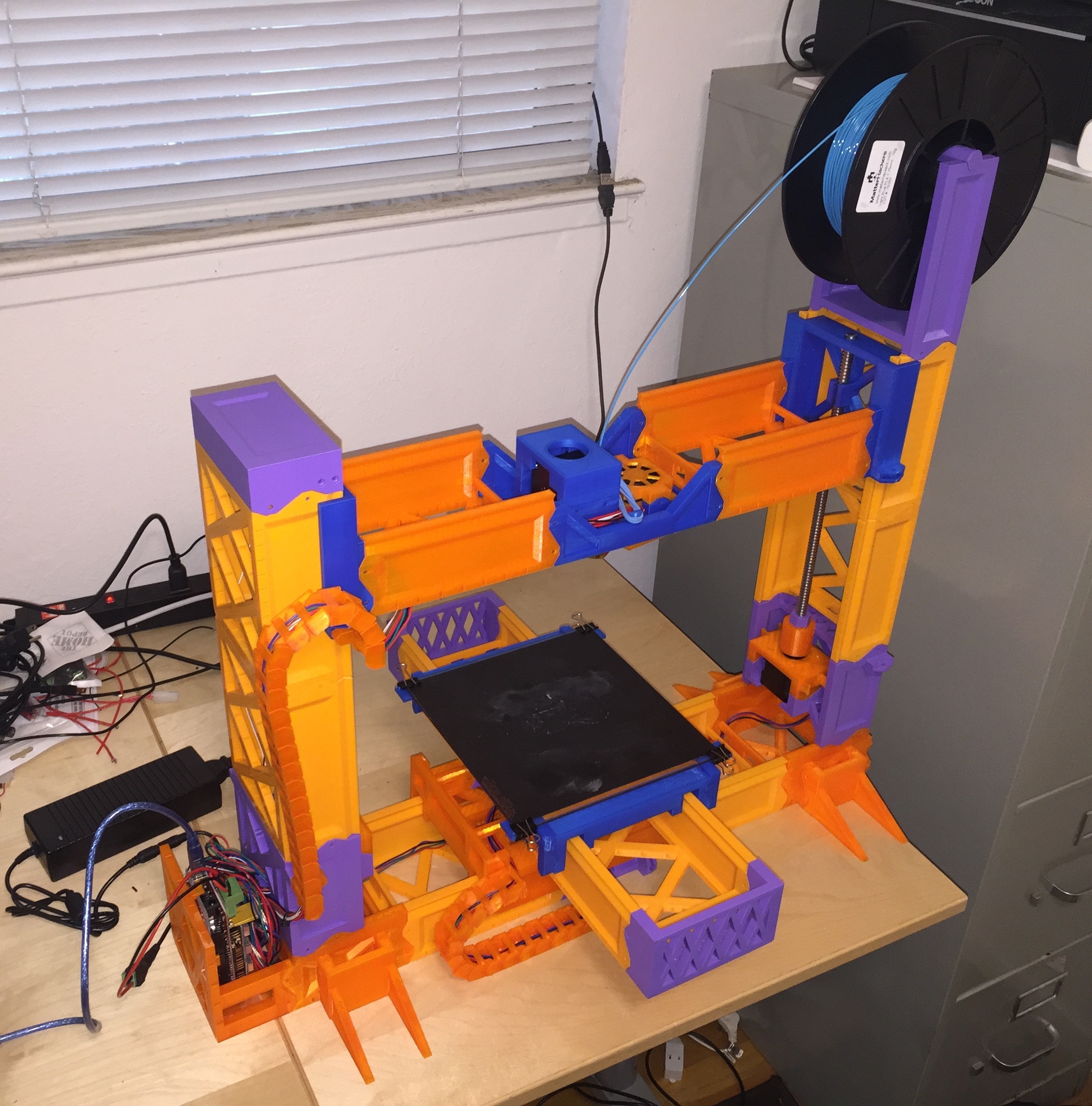

The entire design, as it exists on github at the moment, is almost entirely screw-less. The only remaining screws are two M2.5 screws to hold the Z limit switch, a pair of ACME threaded lifter rods, and the screws holding the stepper motors and extruder hot-end together.

It occurs to me that since I am using two motors for the Z axis anyways, I may be able to remove the lifter rods, and use direct rack-and-pinion drive.

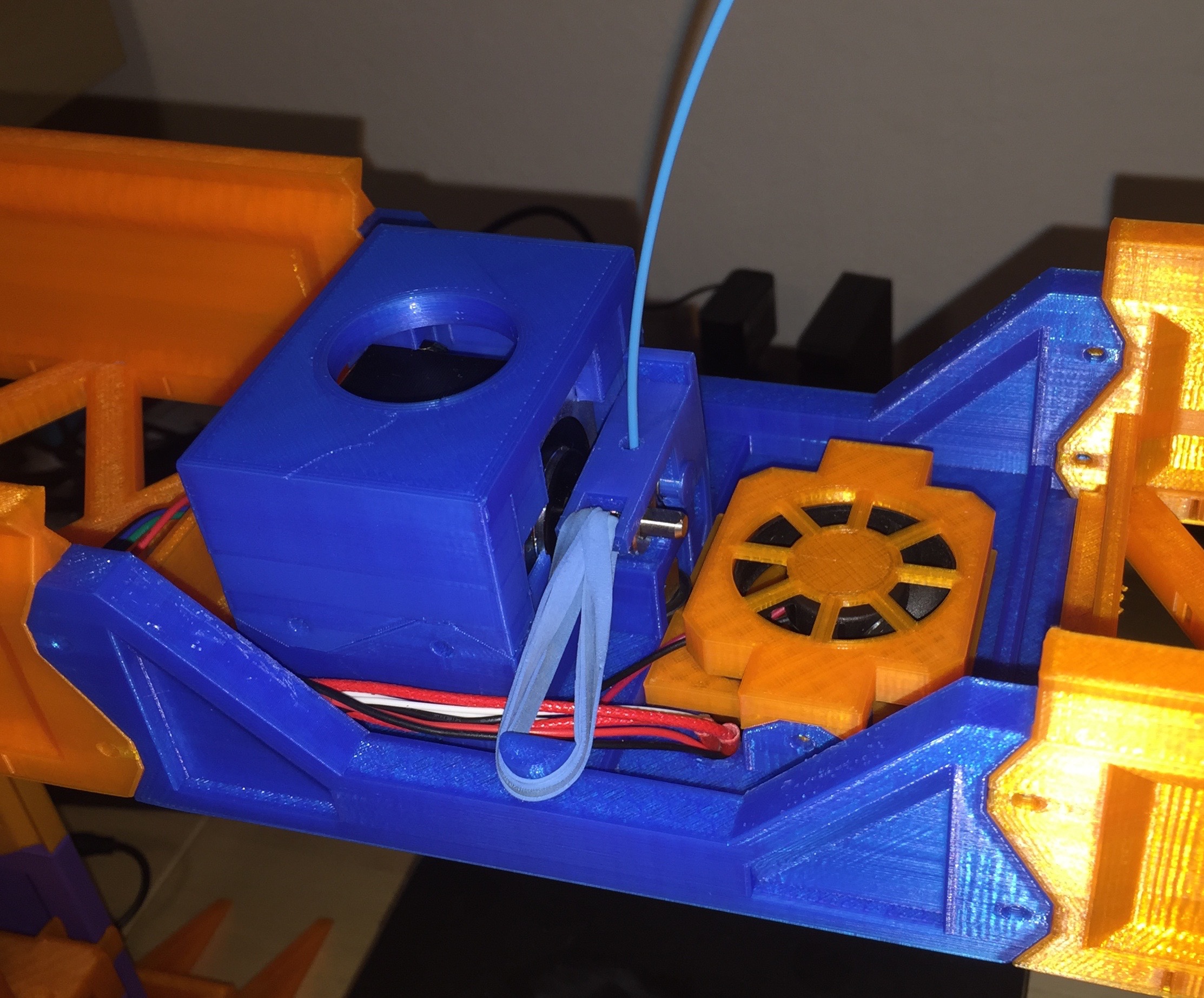

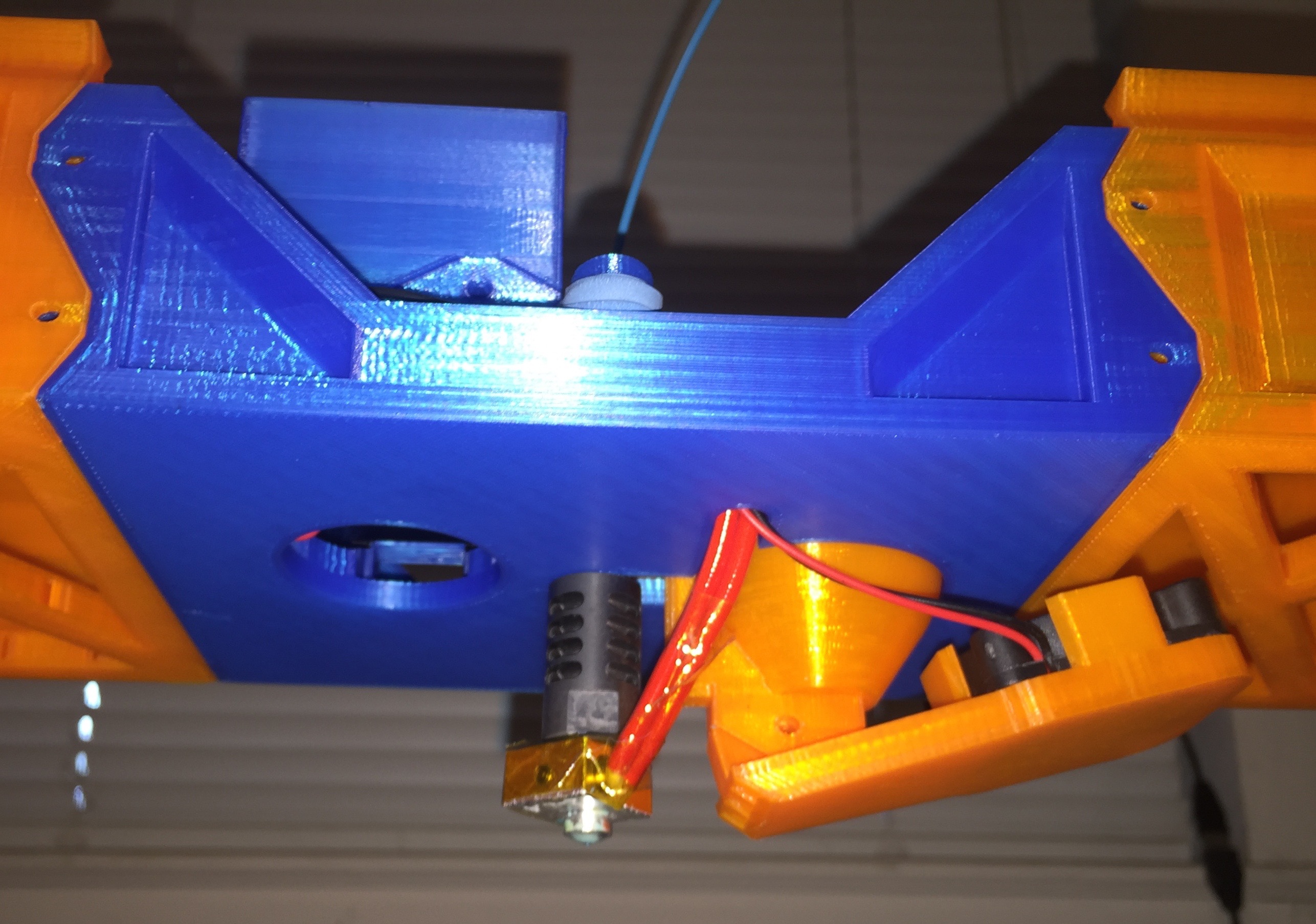

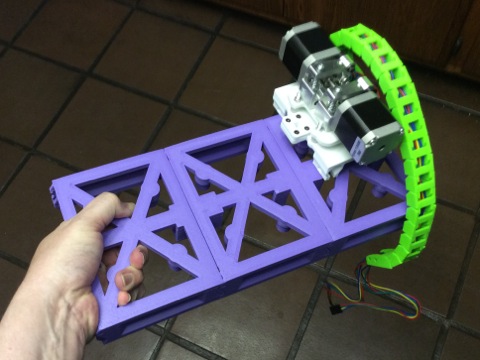

The extruder is now completely printable in PLA!

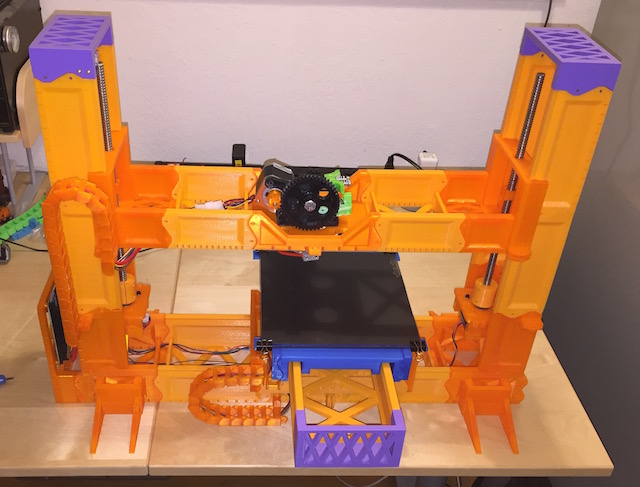

Here's the a photo of the full build so far.

--

2015-07-12

It's Alive! Mwahahahaha!

--

2015-07-03

Success! I was able to get clean full motion from the dual tower design. Now if only my extruder weren't clogged.

--

2015-06-25

New design uses two lifter rods and two rails for the Z axis instead of the previous single-sided cantilever design. Hopefully this will eliminate most of the wobble.

--

2015-01-??

The direct drive design for the Z axis did not work at all. Gearing down the Z axis seems like a very error prone design, upon further thought. Back to the drawing board.

--

2014-10-31

I've assembled a prototype Snappy RepRep, and was able to run it through some motion tests. It works! Mostly. The Z axis wobbles a hell of a lot with the lifter screw, so I'm abandoning that design, and will try a direct drive approach. I was able to turn the printer on it's side, and it was still able to drive the X and Y axes against gravity, so I think that should work for the Z axis as well. If tests prove otherwise, I can always try gearing down the Z Axis.

--

2014-09-03

The eponymous snap joiners have been tested under fire! They take a fair bit of pressure to get to snap into place, but can be joined by hand. For this test, I connected three Z platforms together and put a hefty weight on the end. Once attached, they were solidly together, and didn't even wiggle. Given that the rail parts used for the extruder cantilever have even larger/stronger joiners, and fewer joints are needed, I no longer worry about it holding up!

--

2014-08-31

The X/Y slider got it's first motorized test, and it's a success!