-

Notifications

You must be signed in to change notification settings - Fork 0

[Printer] Ender 3 v2 (Mod List)

2021-12-29

The z-axis stepper and lead screw did not align. The z-axis stepper mounting block was not square on the bottom due to injection molding draft angle. This resulted in the stepper mounting at an angle when screws were tight, and misaligned to the leadscrew. The block was squared using the belt sander, then shimmed 1.5mm to locate the motor shaft more directly under the leadscrew.

To account for the remaining misalignment of the z-axis stepper shaft to the lead screw, the rigid coupler was replaced with a spring coupler and a ball bearing was placed between the motor shaft and the leadscrew to directly transmit the load from the leadscrew (and weight of the gantry) into the stepper motor shaft. YouTube: Alex Kenis - ball bearing trick?

Results: https://twitter.com/HackMelbourne/status/1475814344076054533

2021-12-29

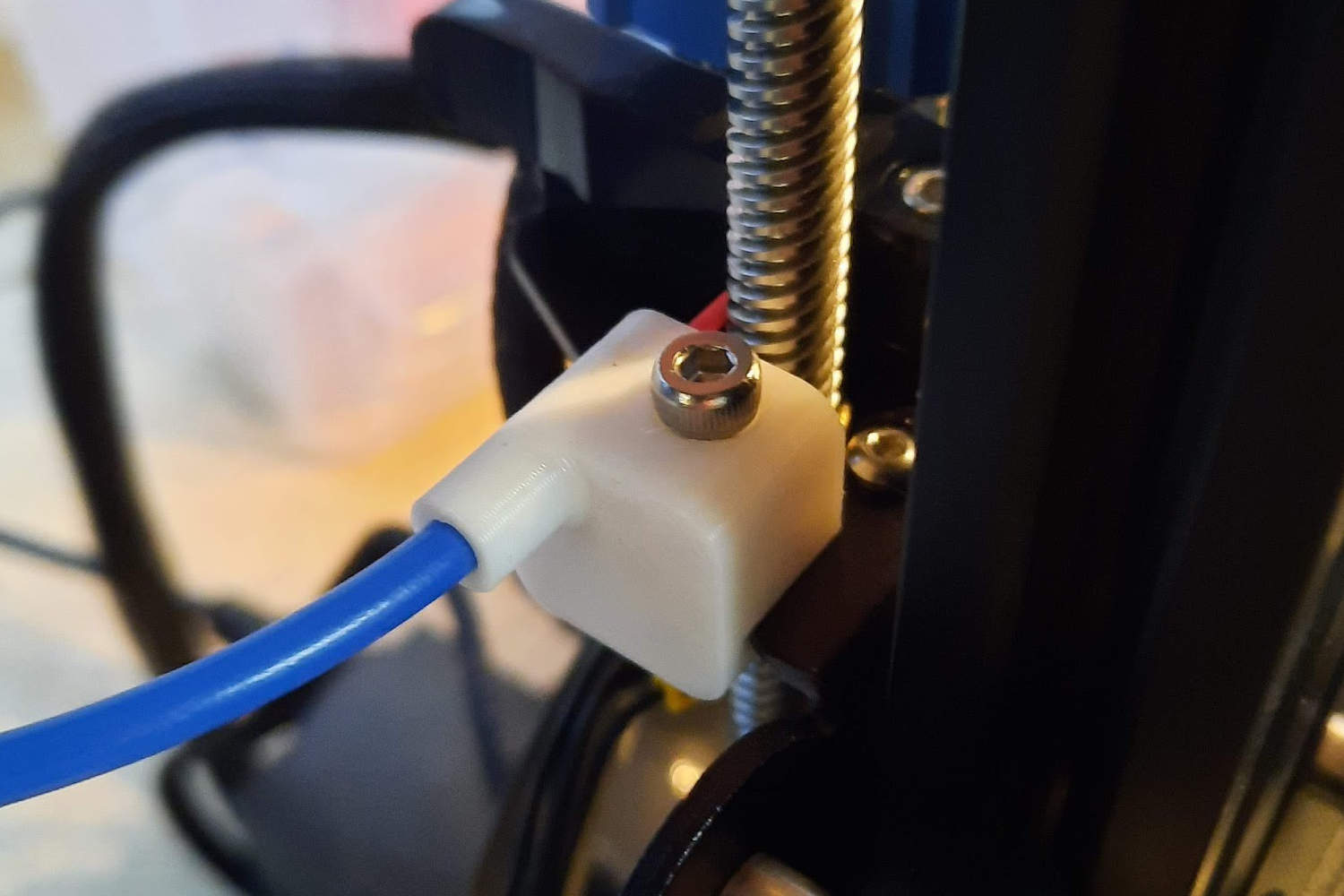

Clip holds an extension of the Bowden tube in-line with the extruder filament path. This prevents the filament from coming into the extruder at a sharp angle, therefore resulting in a smoother path with less resistance for the filament.

Link to Mesh and Fusion 360 model